The Pulse of News

Stay updated with the latest trends and insights.

Why Your Spray Control Could Use a Little More TLC

Transform your spray control with expert tips! Discover how a little TLC can boost your efficiency and results today!

Understanding the Basics: What Is Spray Control and Why It Matters

Spray control refers to the techniques and technologies implemented to manage the application of spray solutions, such as pesticides or herbicides, in agricultural practices. Effective spray control is essential for maximizing the efficacy of these chemicals while minimizing their adverse effects on the environment. By understanding the basics of spray control, farmers and agricultural professionals can apply their substances more accurately, reducing wastage and lowering costs associated with over-application. Key components of spray control include optimizing droplet size, application pressure, and the use of precision equipment to ensure an even distribution of the solution across the target area.

Moreover, spray control matters significantly for several reasons. Firstly, it enhances safety by reducing the potential for drift, which can lead to the unintended exposure of neighboring crops or ecosystems to harmful chemicals. Secondly, proper spray control contributes to sustainability efforts by ensuring that only the necessary amount of solution is used, thereby protecting soil and water quality. Lastly, adhering to best practices in spray control can improve crop yield and quality, allowing farmers to achieve better results and maintain a competitive edge in the market.

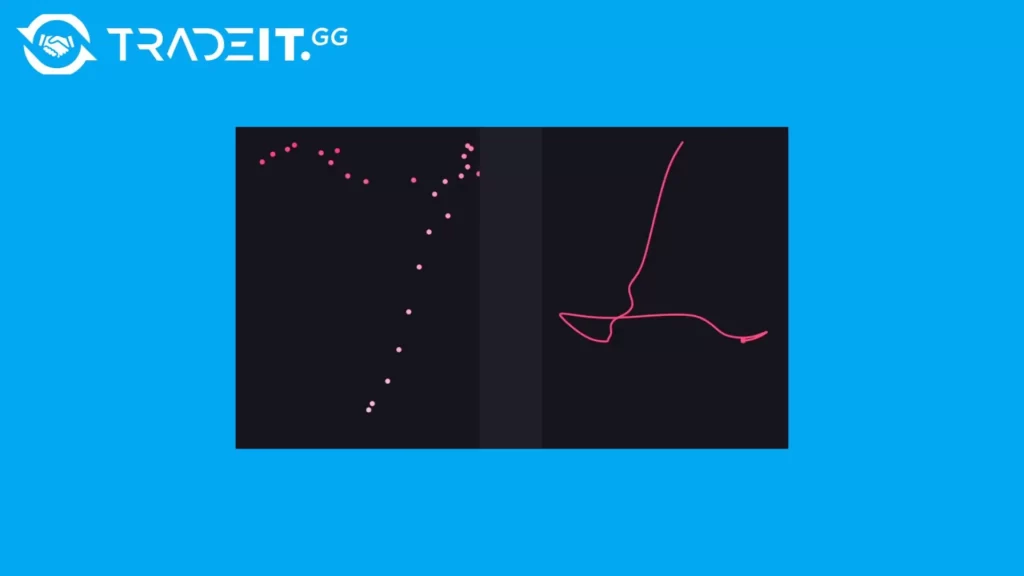

Counter-Strike is a popular tactical first-person shooter game where players can engage in intense multiplayer matches. One of the exciting features players look forward to is the variety of weapon skins, such as the Kilowatt Case, which adds customization and uniqueness to their gameplay experience.

Common Mistakes in Spray Control: How to Avoid Them

Effective spray control is essential for achieving optimal results in various applications, such as agriculture and industrial coatings. However, many individuals and businesses fall victim to several **common mistakes** that can lead to ineffective spraying and wasted resources. One mistake is inadequate calibration of the spraying equipment. Failing to calibrate ensures that the correct amount of product is being applied, which can result in either over-application or under-application, leading to uneven coverage. Additionally, ignoring weather conditions, such as wind speed and direction, can significantly impact spray drift and overall effectiveness.

Another critical error involves neglecting equipment maintenance. Clogged nozzles and worn-out components can hinder performance and lead to inconsistent droplet sizes, negatively affecting the application. To avoid these pitfalls, it's essential to establish a routine maintenance schedule for all spraying equipment. Furthermore, it’s important to choose the right nozzle type for the specific task, as different nozzles produce various spray patterns and droplet sizes. By understanding and addressing these common mistakes in spray control, you can enhance efficiency and improve your overall results.

Is Your Spray Control System Optimized? Key Signs It Needs TLC

In the world of agricultural efficiency, ensuring that your spray control system is operating at its best is crucial. Here are some key signs that indicate your system may require tender loving care (TLC):

- Uneven Coverage: If you notice that some areas of your field are receiving more spray than others, it may be time to evaluate your system's calibration.

- Frequent Clogging: A spray system that frequently becomes clogged can disrupt application efficiency, signaling that it needs maintenance or adjustments.

Moreover, consider monitoring the following factors to further assess your system's performance:

- Pressure Fluctuations: Inconsistent pressure readings can indicate potential issues with your spray equipment.

- Increased Chemical Usage: If you're using more chemicals to achieve the same coverage, this could be a sign that your system isn’t optimized.

Taking proactive steps to identify and address these issues can enhance your spray control system and ultimately improve crop yields.